As AI moves from pilot to plant floor, Campbell Mitchell is showing how Kraft Heinz turns real-time data into smarter, safer decisions.

We're excited to spotlight Campbell ahead of his presentation next week at the American Food Manufacturing Summit in Chicago, IL. As the Head, Food Safety and Compliance, he brings a practical, plant-to-enterprise view of what it really takes to modernize quality systems without compromising rigor.

In his session, Transforming Quality with AI: Insights, Efficiency, and Real-Time Monitoring, Campbell will explore how leading food manufacturers can move beyond reactive checks to proactive, data-driven assurance—elevating product integrity, accelerating release, and reducing waste.

Can you introduce yourself, and share more about your career journey leading up to your current role as the Head, Food Safety and Compliance at Kraft Heinz?

I’ve spent more than three decades leading food safety and quality across five

continents — from dairy and beverages to frozen foods and condiments. My career began as a microbiologist in New Zealand and evolved through leadership roles with companies such as Nestlé, Almarai, Kerry, and Fairlife (a Coca-Cola company), before joining Kraft Heinz to head Food Safety & Compliance for North America.

At Kraft Heinz, I lead programs that ensure product integrity across 31 facilities, representing about 75 percent of the company’s global business. My focus is on connecting people, processes, and technology — building systems that move beyond compliance to deliver superior and trusted products everywhere.

How do you balance the need for fast, real-time predictions with the accuracy required for food safety forecasting?

Speed and accuracy must coexist — but never compete. Real-time insights are valuable only when grounded in science and validated by sound process controls.

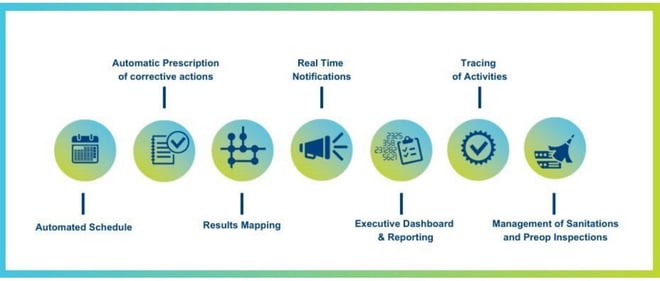

At Kraft Heinz, we’re building toward predictive visibility by modernizing data systems, enhancing plant connectivity, and working with strategic partners such as Mérieux NutriSciences and Ecolab to deploy online tools that deliver real-time data analysis and trending.

"The goal is foresight — enabling our teams to identify and act on potential risks before they affect consumers or operations".

What key metrics do you focus on to evaluate the success of streamlining your quality control efforts?

.avif)

We measure success through a blend of leading, lagging, and business impact indicators. Leading metrics include right-first-time quality, hold-time reduction, and environmental clearance rates. Lagging metrics focus on complaints, audit performance, and regulatory outcomes.

Equally important, we translate these results into the language of business — measuring the cost of poor quality, days on hold, and the financial implications of process variability. When quality becomes quantifiable in business terms, it drives stronger alignment, smarter investment, and shared accountability across the organization. Together, these measures form a “Quality Index” that links safety, consistency, and consumer trust with tangible business performance.

Can you share a success story where real-time tracking allowed for quick action in resolving a product-related issue?

A recent case involved rapid data sharing through our external monitoring platforms. When a hygiene trend deviation was detected, the combination of on-site verification and cloud-based analysis from our partners allowed immediate containment, root-cause identification, and corrective action within hours.

That responsiveness prevented escalation, avoided product impact, and reinforced the value of a connected food safety ecosystem — people, partners, and data all aligned around one mission.

How do you manage and prioritize the large amounts of data generated by your FSQA operations to focus on actionable insights?

Data without prioritization is just noise. We apply a risk-based filtering model to convert information into insight — ranking data by likelihood, severity, and consumer or business impact.

While we continue building a more unified internal platform, external tools from partners like Mérieux NutriSciences and Ecolab already help us visualize performance in real time, spot anomalies early, and focus on preventive action.

"It’s a deliberate journey toward a digital future grounded in shared visibility and meaningful analytics".

How do automated reporting tools ensure you meet regulatory standards more efficiently than traditional methods?

Real-time visibility accelerates empowerment. When our teams see their results live, they respond faster, communicate better, and make decisions grounded in evidence rather than assumption.

It has also reshaped our culture. Data transparency encourages accountability, and accountability drives improvement — turning food safety from a control function into a shared value across every plant.

What are you most looking forward to at the American Food Manufacturing Summit?

I’m looking forward to connecting with peers who are redefining what “good” looks like in food safety and manufacturing. The Summit is a space to share experiences, explore digital and cultural transformation, and learn from others who are pushing boundaries in predictive analytics, sanitation, and regulatory assurance.

For me, it’s about collaboration — the realization that we’re all part of one connected supply chain working to protect consumers and strengthen trust in the global food system.

Don’t miss Campbell's session to see how AI turns quality from periodic checks into real-time, predictive control. Expect practical takeaways you can apply on your lines, clearer compliance with audit-ready data, and faster, smarter decisions across QA and operations.

Visit foodmansummit.com to secure a final spot and join us from November 4-5 in Chicago!

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.jpg?width=380&height=271&name=FoodSafetyCIP-jpg%20(1).jpg)

.png)

-2.png)