Supply chain disruptions in the aerospace and defense sector have emerged as a central concern among leading OEMs. As these supply chains grow, their complexity intensifies, particularly within this industry. While the COVID-19 pandemic underscored the frequency of such disruptions, they have always been a looming inevitability.

The pressing question now is: How can we fortify the resilience of these supply chains?

Honeywell's Vice President of Strategic Sourcing, Greg McDavid, defined supply chain resilience as "the ability to not only respond effectively to a crisis but also possess the foresight, situational awareness, and planning to preempt potential crisis events," at the 2022 American Aerospace and Defense Summit.

Experts cite that essential components to building a resilient supply chain include foresight, thorough planning, and a competent team to implement and manage the strategy. These elements are vital for aerospace companies to effectively navigate potential threats to their production and position themselves for success.

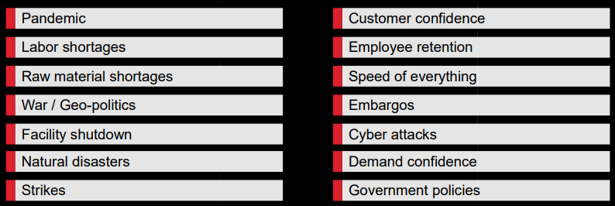

Beyond the most recent disruptor, the COVID-19 pandemic, several significant supply chain disruptions currently confronting the aerospace and defense industry include:

- Geopolitical tensions, specifically the Ukraine War.

- Labor shortages.

- Unsustainable production demands.

- Shortages of raw materials.

- …and many others as listed below.

While most disruptors are unforeseen and unpredictable, when they do occur they can be “catastrophic for not only operational excellence and employee morale but for the company’s bottom line.” When not mitigated by a preparedness plan, supply chains can cost companies up to “45% of a year’s profit throughout the course of a decade.”

©2022 by Honeywell International Inc. All rights reserved.

At the 2022 American Aerospace and Defense Summit, a premier conference for leading industry executives, McDavid offered insights into the future direction of aerospace and defense companies. He emphasized three fundamental pillars for building a resilient supply chain: Planning, Resiliency, and Recovery.

Additionally, other experts highlight the importance of securing the right talent as a crucial factor for aerospace companies aiming to strengthen their supply chain strategy.

The Path to Recovery: Crafting a Detailed Organizational Recovery Plan

McDavid emphasizes the importance of a comprehensive recovery plan, as supply chain disruptions are inevitable. Preparedness, with a clear contingency strategy, is crucial. A key question is how well companies understand and can quickly enact their contingency plans.

Frank McKay of Jabil suggests that companies sometimes "need to abandon old strategies for newer, innovative ones," emphasizing a robust supply chain's importance.

After formulating recovery plans, it's vital for companies to set and follow a timeline for execution and review. While companies have traditionally focused on cost and inventory reduction during crises, the recent challenges highlight the need for agility and flexibility to face global emergencies effectively.

Seed Planting: Cultivating Strong Supplier Relationships

"Seed planting," a term introduced by Honeywell’s McDavid, underscores the importance of regular check-ins with supply bases throughout the chain, ensuring that resilience remains a shared objective.

Being in sync with suppliers is pivotal.

It not only streamlines processes but also fosters agility, flexibility, and a deeper comprehension of operational shifts in the face of disruptions.

Furthermore, this "seed planting" approach fosters greater transparency and fortifies trust between OEMs and their suppliers. The ultimate goal is to satisfy customers while consistently achieving revenue targets.

Getting the Right Talent to do the Job:

Several suppliers and OEMs highlight manpower shortages as a key reason for supply chain disruptions. The A&D industry has seen significant shifts in its talent pool.

During the 2022 American Aerospace & Defense Summit, LTG David Bassett of DCMA highlighted an interesting observation. He pointed out that a significant amount of experience within the industry resides within the older demographics. In fact, the DCMA had accumulated a workforce with a collective experience of 400 years from older generations alone.

However, in an effort to introduce fresh talent into the organization, they made the decision to carry out mass lay-offs. This move aimed to create opportunities for new individuals to bring in their unique perspectives and insights. This strategic approach by DCMA serves as an example for other leading OEMs in the A&D industry.

Moreover, it is imperative to have highly skilled engineers, visionary procurement leaders, and adept supply chain managers who possess the ability to anticipate challenges and devise effective strategies. The secret to safeguarding a supply chain strategy from future disruptions lies in the continuous recruitment of top talent and the provision of ongoing training, guaranteeing the organization's long-term prosperity.

What does the Future of Aerospace and Defense Supply Chain Resilience Look Like?

An organization's supply chain strategy is inherently tailored to its industry. Nonetheless, the foundational principles of building a resilient supply chain are universally applicable.

The essence lies in maintaining preparedness, cultivating agility and flexibility, and ensuring alignment with your supply bases and suppliers. This alignment fosters cohesiveness as you confront potential disruptions. Ultimately, having a competent team supporting you is vital.

Such a team guarantees the successful execution of your plan and continuously identifies areas for improvement, enabling the organization to adapt to any evolving circumstances.

As we look ahead, what do you envision to be the latest supply chain trends within aerospace & defense?

If you're curious about the future of A&D supply chains, join us at the American Aerospace & Defense Summit and gain exclusive insights from top OEMs in the industry!

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.png)

-2.png)