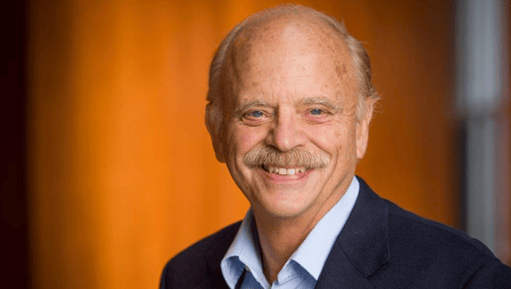

Throughout our lives, we are constantly reminded of the importance of pursuing a career in something that we are passionate about. While this may be easier said than done, this mindset is especially apparent in Andrew Skibo, Chief Manufacturing Officer at FluGen Inc.

Attending the American Biomanufacturing Summit as a key speaker since 2017, Andrew Skibo is a seasoned and well-respected executive within biopharmaceuticals. A few weeks ago, we had the privilege of sitting down with Andrew for a very insightful, engaging, and inspiring conversation about his career navigating the bio industry.

To say that Andrew is an inspiration is an understatement.

With over 40 years of experience working for household names including AstraZeneca, Amgen, and Genentech and five years of freelance consulting for his passion, Andy has had the career journey we all strive for.

Throughout our conversation, Andy provided many fantastic insights, and above all, this much was clear: working 20 hours a day will never feel like work if you are in a position you truly love. Having this mindset, and a true passion for the job you are working in, ensures that you bring your best self to your job day in and day out. This is a quality we believe all great leaders possess, and proudly express through their work.

Now, let’s get into the interview and learn more from the words of Andy Skibo.

Thank you, Andy, for meeting with us. Could you begin with a brief introduction about yourself and your impressive career journey?

I'm Andy Skibo. I've been in the pharma industry since 1976, so I'm an antique. I graduated from MIT in 67 and got my masters in 68. I completed my Masters’ in one year, thanks to Lyndon Johnson, and the war going on over in Southeast Asia.

Funny enough, I actually did not start in Pharma. I worked in the chemical industry, and if you go back into ancient history, a few of my patents are in Polymer Science.

My polymer patents got me into project management, and as I worked in project management and development, I started to do a lot of work for Big Pharma. This was back when it was pre-bio, which meant it was mostly small-molecule, organic synthesis. From that, I wanted to get into what I call the “owner’s side,” or the manufacturing side. At the time, I was in charge of sales for Big Pharma, which meant I couldn’t apply to Big Pharma. Luckily, I was not in charge of sales to the budding bio-industry, because I wanted to apply to bio as it was new and different.

Applying to bio meant taking risks because everyone said bio would never work. A friend even told me I was crazy and that it would take 30 years before the industry took off. Despite this, while deciding between 4 offers, I picked Genentech. It was 1982, and they were far enough along that the risk was lower, but it was still early enough that it was a highly leveraged play.

By choosing the bio-industry and Genentech, I inevitably took a risk early on in my career, and it paid off. If you’re going to invest your career in an area that’s been established for 40 years, there’s much less to be leveraged in the long haul, and as a risk taker, that isn’t much fun. To me, Genentech was the right place to be. We were the ones who developed large-scale mammalian cell culture, even when people said it couldn’t be done.

Early Genentech were the great years, but as they matured into a flat spell, I left the company and started my own firm, which helped other little firms figure out how to build their first facility. I sold that firm to Life Sciences, which was a new engineering firm that became the largest firm at the time designing and building these facilities. From there, I moved on and became the president of Foster Wheeler Life Sciences Division, because work was moving globally and Life Sciences wasn't a global firm. I then went from Foster Wheeler to Amgen, and then to MedImmune/AstraZeneca, which is where I finished my career.

I retired on April Fool's Day 2019, at the age of 74, and joined FluGen as their Chief Manufacturing Officer on April 2nd. I work with FluGen on a consultancy basis, and I also consult for AstraZeneca and two other firms. In a sense, I never really stopped working for AstraZeneca.

The past ten years of my career have been focused on manufacturing operations and supply chain design, with de-risking supply chains being one of my main topics.

Could you tell us about any mentors you have had in the past that have been pivotal to your leadership journey?

There are two mentors whose names I remember from my early days in Monsanto and Fluor Daniel. I’m terrible with names, so if I remember a name from 30 or 40 years ago, they were really important to me.

The first one is Chet Woodworth. He ran the large development team at Monsanto's Saflex® Division. For some reason, Chet had the courage to give a 22-year-old graduate of MIT the charge of one of the pilot plants. It was a new technology that had to be developed, as it was not working well in large-scale plants. This was when I developed my patents, and it gave my career a very early start.

When I joined in 1968, the industry was very conservative, so the fact that Chet dared to give a new grad that kind of exposure inevitably helped shape my career and learning journey. Chet was the one who pushed us to look at the edge of what was known, and then figure out how to get beyond that. Sometimes the answer is actually very simple, and those simple steps forward are what led to my patents being developed. .png?width=354&height=237&name=Add%20a%20little%20bit%20of%20body%20text%20(23).png)

My second mentor was Bob Perkins, head of all project management at Daniel and Fluor in Greenville, South Carolina. I was a process engineer, maybe 6 or 7 years out of school at the time, and new to large project management. I sat there with two MIT degrees figuring I knew how to run a team. Bob Perkins was an old project manager who very quickly made it clear that I didn’t know how to run anything. He was the one who taught me to “Look at the detail, but do not live in the details. Don't get lost in the weeds Be able to dive down into the details and then figure out how to manage it at 100,000 feet.” Even as a senior executive, even with glorious titles like EVP of Operations, solving a problem in a big bio plant often involved gathering the youngest and the brightest, the middle experienced folks, and then a few of us with not much hair left, and looking at the details from 100,000 feet. This is something I’ve used throughout my career, and I owe that to Bob Perkins.

Those are the two names that I would remember as real mentors in shaping my career, and, as I said, they weren't from the bio end of the business.

How does the industry look today in comparison to roughly 40 years ago?

In some ways, it looks the same.

The technologies being introduced are new in the same way bio was new 40 years ago. Bio, of course, is now established and considered old school. So when we get into the mRNA's, gene therapy, and gene splicing we are working at different scales. It feels the same seeing things being new and developing, having lived through new and developing before.

You almost feel at home looking at some of these little startups, which is why I love working with FluGen. Working with companies that started with 6 or 15 people, and maybe now have 50 and a brilliant idea, but don’t have the money to execute it. Helping them take the next steps feels like the “new” of 40 years ago.

Of course, the technology is totally different, and you’re inventing the technology as you go, so it's new. But that’s how industries grow. Ultimately to me, the industry is new, but the same.

“Ultimately to me, the industry is new, but the same.”

What does the future of the biopharma/biomanufacturing industry look like for you?

I think what we’re going to see is two trains in the industry.

One, we are going to continue having a large number of therapeutic products that are made at large scale metric tons of product. We’ve barely begun to scratch the surface of these. The teams I was with at MedImmune and AstraZeneca launched 8 new biologics in the last 4 years. Many of them were already in flight. AstraZeneca asked me to stay on for the launch of the first few to make sure they happened. The large-scale production of tons of therapeutic products is still going to be a major part of the industry for certainly the next decade or two.

At the same time, you have gene therapy that is operated at very small scales, which is going to require a different kind of management mentality. This may not be as globalized of a supply chain as the large-scale plants. It will be a globalized industry, but it's so patient-to-.png?width=388&height=259&name=Add%20a%20little%20bit%20of%20body%20text%20(22).png) drug time-sensitive, that I think it is going to be much smaller scale and geographies. It’s going to require a different kind of supply chain thinking in the industry. It fascinates me because it is a combination of BioPharma, with all the CGMP and the compliance and total control of what you do, and Amazon delivery.

drug time-sensitive, that I think it is going to be much smaller scale and geographies. It’s going to require a different kind of supply chain thinking in the industry. It fascinates me because it is a combination of BioPharma, with all the CGMP and the compliance and total control of what you do, and Amazon delivery.

If you think about personalized medicine, you have to extract the plasma, spinal fluid (or whatever it is you are taking out of a specific human), and you have to track that into the manufacturing plant. This specimen remains associated with a specific human throughout the supply chain, including distribution back to that same human. The older plasma fractionation business covers the first part of that, because they do have to track a specific human's donated blood up to the pooling stage. That is necessary in case a donor's blood is found to be contaminated. Once pooled, however, the tie to a specific human is lost. For gene therapy, it remains a human dose and has to go back to the same human, and if you screw it up, A - you may kill someone, B - you certainly aren’t going to cure them, and C - the FDA is going to come in and put a chain around your door.

Amazon knows how to do that, they track a specific package to a specific human as a routine course of business. Pharma doesn’t know how to do that. So, if I had to build a supply chain group for that kind of industry, I’d be hiring two kinds of people. I’d be hiring one of me, and I’d be hiring someone like me, but from Amazon. Because the new supply chains have to be both.

Further, I think we must manage risk in the supply chain more knowledgeably and aggressively than we have. Some firms got burned during COVID because their very diffused globalized supply chains didn’t work so well at a national level. So, supply chain remains an issue - especially for globalization - that we have to be realistic about. The cost benefit involved is the ability to reliably supply. Our products are not cost-sensitive, they are guaranteed delivery-sensitive.

In small companies, you don't get into this heavy financial crunch of squeezing the last dime out of the supply chain because you’re just trying to make the product, and making the product is your first priority.

Once you’re up alive and well, you have this counterbalancing pressure of “where can I save costs” in manufacturing and finance. Operations must resist the pressure to take risks right up to the edge based solely on cost. At the bottom line, the dollars are in the delivery of the product. Even if you want to put patient health and safety aside, the dollars are so high in pharma, that failure to deliver is a major financial failure, I think that we still don’t get that risk right.

What inspired/drove you to create your own Biopharma Operations consultancy, and what advice would you give someone who is looking towards the path of entrepreneurship?

My inspiration behind the consultancy firm is twofold.

The first being that a lot of people wanted me to do it, which made it hard to walk away from.

The second is that I really just love the industry. And that's advice I give to anyone in their career.

Pick something that you are passionate about. There are going to be brutal weeks, months, and years in your career. There are going to be days where you're working 20 hours. There are going to be days when you have senior management wanting to rip out a kidney with no anesthesia. And if you don't like what you do, and you’re working with a team where there are people who love what they do, they're going to outcompete you. There's no way you can force yourself at 35 or 40 years old, to work as hard at something that you don't like anymore to compete against someone who loves it. To them, 20 hours of work is just more fun in the day.

So, I got into consultancy because I just like doing it. This is my golf and my sailing. I just like doing this. I don't want to be the oldest guy on the block, so if I ever become non-useful, or my knowledge gets outdated, well, I hope somebody kicks me in the shins.

Essentially, it was a combination of there being a need, I wanted to do it, and I didn't want to stop. I work approximately 40% of full-time. And I like what I do. As you can probably tell.

With your session being centered around career growth and how to get ahead in the industry, can you provide some advice for anyone interested in further establishing themselves as a leader in their space?

I would give four starting points:

1. Pick an area you are passionate about. You're not going to do well if you're not passionate about the work you are doing.

2. Pick new. There’s an exciting element of rising into a business and a career. If you are planting yourself into a well-established industry, an industry beyond its peak, it'll be a good career, but it's not going to put you in a position where you've done something different. So pick something that is new, and that is leading edge. This means taking risks because you're going to guess wrong sometimes. But, it is better to take a risk on something you really want than take the safe way out and settle. You know, my dad wanted me to work in the steel industry when I got out of school. Guess where that would have taken me.

3. Take measured risk. Now, it is easier for me as a Boomer generation to say this because we are all wired to take risks. Compared to a late-stage Millennial, where people are generally wired to take a safer way out. Regardless of which generation you are in, I would encourage you to take measured risks. As I said, I chose Genentech over three other offers. I thought it had the best chance of giving me an exciting career, and it was a heck of a lot more of a risk than working for Merck or Pfizer. So, wherever you are in your career, just remember to take measured risks and don't be afraid of failure.

4. Be resilient. Even if you are working as an expert at something, there will be failures. You are going to get fired sometime in your career. We all do. Learn from it. Figure out what went south and use it as an opportunity for a glorious learning curve.

"And if you don't like what you do, and you’re working with a team where there are people who love what they do, they're going to outcompete you. There's no way you can force yourself at 35 or 40 years old, to work as hard at something that you don't like anymore and compete against someone who loves it. To them, 20 hours of work is just more fun in the day."

We’d like to extend a big, heartfelt thank you to Andy Skibo for taking the time to share his inspiring career journey. I think we all have something to learn from his words, regardless of what stage we are at in our careers.

If you want to hear more wise words from Andy, be sure to attend the American Biomanufacturing Summit, April 10-11, 2024 in San Francisco. Andy’s session is titled, “Career Growth And Development in Biomanufacturing,” and will dive deeper into some of the insights he provided for us during the interview.

So, will you be joining us at the 10th anniversary of our summit?

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.png)

-2.png)