It’s time to think differently about manufacturing.

Taking an idea from prototype to production is no longer bound by the constraints of traditional manufacturing methods. In the era of Industry 4.0, companies are mitigating risk, cutting costs, and speeding time to market with 3D printing – a process that is predicted to revolutionize the world of production.

Since its creation in 1983, 3D printing has evolved from a one-dimensional service used for rapid prototyping to a $7.3 billion industry with a footprint in a wide span of industries. Its evolution now helps power the world of manufacturing, increasing innovation and promoting efficiency and sustainability across the globe.

Benefits

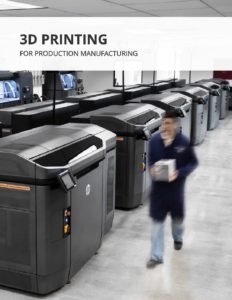

- Speed: One of the main benefits of additive manufacturing is the speed of which parts can be produced compared to traditional manufacturing methods. With Forecast 3D’s 3D Manufacturing Center (powered by 24 HP Multi Jet Fusion 3D printers), customers can get tens of thousands of parts in days, whereas traditional manufacturing methods like injection molding, often done overseas, typically take a month or more to complete

- Design Flexibility: 3D printing allows for the creation of extremely intricate designs and complex geometries that would often be complicated or even impossible to produce with traditional manufacturing methods. With additive manufacturing, customers can reiterate their designs and have updated parts quickly. With injection molding, tooling changes are required for every little design tweak, often resulting in several more weeks of waiting. The design flexibility of 3D printing is also highly valuable for unstable designs.

- Manufactured Locally: With Forecast 3D’s 3D MFG Center, parts are made in the USA. Localized manufacturing can save time, money, and confidence in the protection of IP.

- Cost: Depending on the design and quantities needed, using additive for production can be less expensive. This is especially true as products are ramping up and quantities are lower. Utilizing 3D printing in your manufacturing process can also free up cash used for high tooling and warehouse costs.

We worked with Forecast 3D prior to the American Aerospace & Defense Summit 2019 to create this e-book on “3D Printing for Production Manufacturing”.

Click through to access the full e-book here.

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.png)

-2.png)