A software-based system for managing safety in manufacturing organizations may hold the key to unlocking efficiency, improving processes and creating safer workplaces that, at the end of the day, puts money back in the pockets of these businesses.

Experts say that Safety Management System (SMS) support the ability of manufacturing companies to help change leadership thinking and cultures in reducing the number of workplace injuries through increased awareness of, and involvement in, safety programs, and ultimately elevating the important of and commitment to safety across entire organizations.

In the U.S. a total of US$170 billion is spent by business each year on occupational injury- and illness-related costs that eat away at net earnings. The National Safety Council reports that a dollar invested in an SMS – and the subsequent potential improvements that can be achieved in overall safety management – returns anywhere from between $2 and $6. These savings come about as a result of management accountability, cultural safety impacts, and ultimately reduced workplace injuries and fatalities.

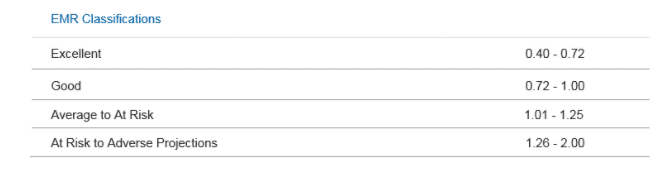

Workers’ compensation premiums are a great example of where potential for savings can be achieved. Premiums are typically determined by multiplying the base premium (set by the prevalence of injuries within a particular industry) times the Experience Modification Rating (EMR), a metric determined by a company’s actual history of injury incidents). If the company’s current EMR is greater than 1.0, there is significant room for improvement and the potential for savings on premiums (see Table 1).

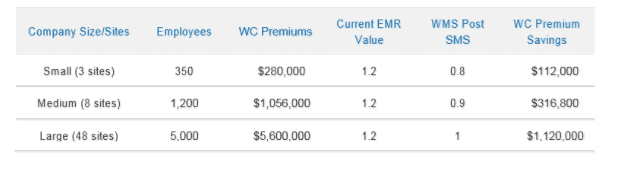

Table 2 provides examples of the potential impact of SMS on lowering EMR ratings to achieve company-wide savings.

Based on achievement of these level estimates of potential year over year savings, the initial software and maintenance investment costs could be returned over a three-year period.

A new whitepaper from Intelex, “Smart Spending for Safety in Manufacturing,” details more ways that your organization can save costs by implementing an SMS solution and how to build out your SMS Return on Investment. Get your copy now: http://bit.ly/2FSmpbR

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.png)

-2.png)