In most high-mix discrete manufacturing, the concept of plant floor management can be misleading, as schedules cannot be carried out, production analysis is often too late to create impactful changes, and there is no visibility into bottlenecks, WIP or order status.

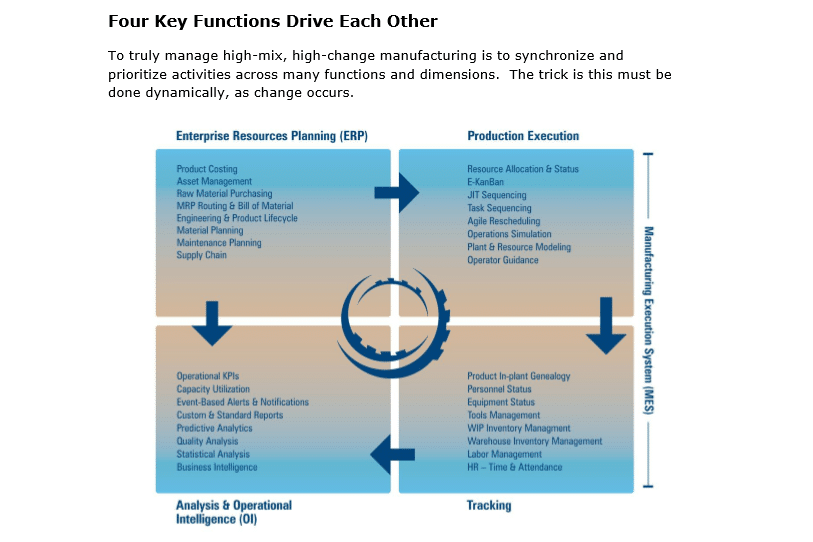

Fortunately, Real-time Dynamic Scheduling is now available and can create improvements in plant floor management by coordinating among four functions: production planning, execution, tracking, and analysis.

For more information, read Julie Fraser’s white paper on “How Real-time Dynamic Scheduling Can Change the Game: New Software Approach to Achieving Stable Success in High-Change High-Mix Discrete Manufacturing,”

click here.

%20(1).png?width=773&height=112&name=Generis%20Logo%20full%20Colour%20(Large)%20(1).png)

.png)

-2.png)